|

Search For Isolated Fractionally Charged Particles |  |

|

Search For Isolated Fractionally Charged Particles |  |

Microdrop Technology for Fractional Charge Searches

Generating the fluid drops for performing the charge measurements was one of the most challenging aspects of the experiment:

- The optimal range of drop sizes from 7 - 20 microns in diameter is far smaller than what the inkjet and laboratory micro-dispensing manufacturers have produced as marketable products.

- The drop generator has to operate without maintenance for months at a time.

- The drop ejector hardware should put only chemically inert surfaces in contact with the search fluid.

- Since exotic fluids may have to be tested, the drop ejector should have a very small minimum operating volume.

- Since testing multiple fluids is planned, the drop generator should be easy to replace fluids in or be inexpensive to replicate.

- The drop generator should be able to produce controllable 2 dimensional arrays of fluid drops.

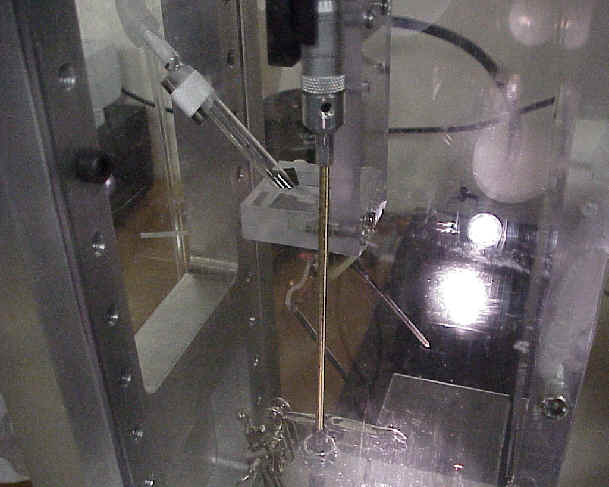

The first drop generator that we constructed was built as a research tool able to produce continuous fluid jets as well as make drops by both acoustic fluid jet breakup and by drop on demand single pulse ejection. The apparatus had the provision for changing ejection aperture plates and for operating at high values of positive and negative pressure.

While not optimal for use in fractional charge search experiments due to its complexity, large required fluid volumes, and metal construction, this machine provided valuable experience and data to us about the engineering fundamentals of drop ejection.

The experience obtained from research with this machine was used to design the next generation of drop ejectors.

The drop generator design used in our current work are refinements of a basic ejector design originated by Steven Zoltan of the Clevite Corporation in 1972. Our versions utilizes a thin film coated micromachined silicon ejection aperture fused to a glass reservoir tube. A piezoelectric element adhesively attached to the reservoir tube provides the pressure pulse that ejects the fluid drops. Variations of this basic design have operated with fluid reservoir volumes less than 1 microliter. The drop sizes generated have ranged from 2 to 50 microns in diameter. Fluids ejected have included aqueous liquids, silicon oil, organic solvents, and viscous fluid-particle suspensions.

Some of the drop ejectors designs constructed for our experiments. The drop ejector on the far left was constructed by welding an ejection aperture to the end of a standard Pasteur pipette. It is not necessary to completely fill the pipette for drop ejection to occur. As little as a microliter of fluid in the tip of the pipette is a sufficient volume to eject fluid drops.

Drop ejector with charge induction electrodes. One electrode is connected to the silicon wafer and the other forms a ring in front of the ejection hole.

These electrodes allow an electric field to be set up along the fluid jet to control the charges of the ejected drops.

A series of smaller drop ejectors were designed and tested for applications requiring arraying the drop ejectors or physically translating them.

Details of the micromachined ejection aperture. The silicon aperture is thermally welded to the glass reservoir tube.

The diameter of the silicon structure is 2.5 mm.

The ejection hole diameter is 50 microns.

One of the requirements of the experiment is to generate controllable 2 dimensional arrays of fluid drops. The methods most often used in industry involve physically moving the ejectors and using multiple ejector channels. We have found a simple method of obtaining the droplet grids that we need by orienting the drop ejection direction sideways and electronically modulating the drive pulses to the piezo electric element such that the distance from the ejection aperture that the drop forms is a function of these drive parameter values.

- The horizontal grid spacing is defined by the degree of modulation.

- The vertical spacing can be defined by setting the drop mass and the rate of drop generation.

- The number of columns is set by the number of discrete values sequenced through.

In order to test the ground solid material in a Millikan apparatus it must be put into the form of a liquid. A fluid suspension containing finely ground solids is superior to that of a dissolved solution because it reduces the possibility that the atom with an attached fractional charge will react or bind to the materials used to construct the droplet ejector. Ideally the ground material should be made into a stable colloid. Since this was found to not be possible for some of the materials we are interested in we have developed ways to artificially stabilize and eject non-colloidal suspensions.

Ejecting fluid particle suspensions as opposed to pure liquids has some unique problems such as orifice clogging, particle settling, aperture degradation and film buildup on the ejection device surfaces. We have had to develop technologies for:

- Pulverizing minerals to submicron particle sizes.

- Suspending these particles in ejectable fluids.

- Dynamically resuspending unstable colloids without disturbing the drop ejection process.

- Minimizing particulate buildup on surfaces

- Optimizing the ejection apertures for minimum fluidic impedance with viscous fluids

- Optimizing the aperture construction to minimize the tendency to clog

One fluid that we were particularly interested in synthesizing and developing methods of ejecting was a suspension in oil of ground carbonaceous chondrite meteorites.

We succeeded in this task utilizing the following techniques:

- Supersonic air jet pulverization of the meteorite into submicron particles.

- Suspension of these particles in a fluid mixture consisting of commercial low viscosity mineral oil with 5% Castrol motor oil added for its surfactants.

- Dispersion of these particles using a high shear rate rotary colloid mill..

The picture to the right shows a drop generator ejecting 20 micron diameter drops of this meteorite suspension.

A number of the technologies on this page have been the subject of patents filed by the Office of Technology Licensing at Stanford University. OTL staff should be contacted for obtaining additional information about these devices or techniques.

[SLAC home] [MPS home] [Hist] [Phys] [FCMat] [Apparat] [TestMat] [Microdrop] [Results] [Team] [Refs]

[MPSPhys] [MSPAppat] [MPSRefs]

April 30, 2007

Stanford Linear Accelerator Center

Website maintenance: erlee@SLAC.stanford.edu