Emittance Measurement

Software

Engineering Design

Document

1 Scope (Levels of Design Detail)

This document describes the requirements (design details to

be added later) of the high level software application that measures,

calculates, and displays/outputs emittance and Twiss parameters. Additionally, the software application

can perform betatron matching.

1.1 Introduction

“The transverse electron emittance can be measured along the

LCLS accelerator at various locations using various techniques. The locations, components, and methods

are summarized here. The method

can be a multi-screen (or multi-wire) technique, where transverse beam size

measurements are made at ≥3 different, but neighboring locations, or it can be

a quad-scan (single-screen or single-wire) method, where the transverse beam

size is measured at one location for ≥3 different upstream quadrupole magnet

gradient settings. These standard

techniques are used to measure the time-integrated, or projected emittance over

the full bunch length. In addition,

the quad-scan method can be used to make a time-sliced, or slice-emittance,

measurement, where the transverse beam size in one dimension (x or y) is sliced

as a function of its extent in the other transverse dimension (y or x). The slice-emittance measurements are

identical to the projected emittance methods, except that the emittance is

calculated for every beam slice (typically 10 slices).”[1]

1.2 References

LCLS High

Level Software Applications Requirements, P Krejcik / B. Dalesio, PRD

1.1-307

Emittance Measurements in the LCLS, P. Emma, PRD

1.1-012 (url after posting)

XAL

Accelerator Class Hierarchy

1.3 Assumptions

This document assumes the use of the Java-based XAL

software, to be modified for LCLS.

XAL, developed by the Accelerator Physics Group, Oak Ridge National

Laboratory, is a Java framework for developing accelerator based applications,

provides a common toolset (including pv logger), and supports online modeling.

It is important to note that XAL has a distributed, three-tier Model/View/ Control (MVC) architecture. The data access, or Model layer of MVC (“Model” in this context should not be confused with the optics or online model), is comprised of the “standard machine format” (smf) package which contains the classes which access the accelerator nodes (devices) at the lowest level using java channel access (jca). This smf package may also be accessed via matlab. The User Interface (UI), or View layer of MVC is rendered via XAL’s common application framework with Java Swing GUI components. The View layer could also be rendered via matlab, with a data access layer using either smf or labca. The MVC Control layer will be comprised of various classes in support of each component and its associated UI. Control layer classes that are not in support of UI (as well as smf) must have a public Application Program Interface (API) to support programmatic access.

2 Requirements

2.1 Physics

2.1.1 Emittance Measurement Locations and Configurations

“Table 1 summarizes the

various locations and types of transverse emittance measurements presently

envisioned throughout the LCLS accelerator. Here “WS” indicates a wire-scanner and “OTR” or “YAG”

indicates a screen.

Table 1. Summary of emittance measurement

locations and methods. All quadrupole magnets varied here have their own

separate power supplies. Entries

above the double line are needed in 2007, while entries below this point are

needed in 2008. All quadrupole

magnets are new for LCLS, except those noted as existing.”[2]

|

method |

profile(s) |

region |

plane |

quadrupole varied |

Projected, Slice, or Both |

|

quad-scan |

YAG01 |

gun |

x or y |

SOL1 |

P |

|

muti-wire |

WS01,WS02, WS03 |

injector |

x or y |

- |

P |

|

muti-screen |

OTR1,OTR2, OTR3 |

injector |

x or y |

- |

P |

|

quad-scan |

WS02 |

injector |

x |

QE03 |

P |

|

quad-scan |

OTR2 |

injector |

x |

QE03 |

B |

|

muti-wire |

WS11,WS12, WS13 |

post-BC1 |

x or y |

- |

P |

|

quad-scan |

OTR11 |

BC1 |

y |

Q21201* |

S |

|

quad-scan |

OTR12 |

post-BC1 |

x |

QM12 |

B |

|

muti-wire |

WS21,WS22, WS23, WS24 |

pre-BC2 |

x or y |

- |

P |

|

muti-wire |

WS044,WS144, WS444, WS544 |

post-BC2 |

x or y |

- |

P |

|

muti-wire |

WS31,WS32, WS33, WS34 |

LTU |

x or y |

- |

P |

|

quad-scan |

OTR33 |

LTU |

x |

QEM3V |

B |

* Existing (legacy) linac quadrupole magnet.

Note: It is not required for the existing

linac quadrupole magnet to have control from LCLS in time for December 2006

injector commissioning.

2.1.2 High Level Software

2.1.2.1 Transverse emittance reconstruction[3]

Š Should

be adaptable to any part of the machine where there are beam profile

measurements available

Š Two

types of emittance measurement depending on whether a single beam profiling

device is used in conjunction with a quadropole scan, or using multiple beam

profiling devices distributed in a transport line.

Š Also

– slice - A single beam profiling device (OTR, YAG) whose projection is

sliced “n times”, where “n” is user selectable

Š Initiate

beam profile scans using default or user supplied scan ranges and settings.

Š Beam

sizes as a function of quadropole strength or or profile monitor location are

processed along with online model information to return emittance and twiss

parameters of the beam.

Š Output

user interface to determine errors and quality of measurement.

2.1.2.2 Beta matching[4]

Š Uses

twiss parameters from emittance measurement in combination with online optics

model to predict changes to user specified matching quadropoles to achieve

design twiss parameters at a user specified location.

2.2 Security

Š Who

is allowed to do invasive operations in the production system – from the

Control room only? This has some affect on the software architecture (ie,

monlithic versus stand-alone application designs) .

2.3 Functional

2.3.1 Block Diagram

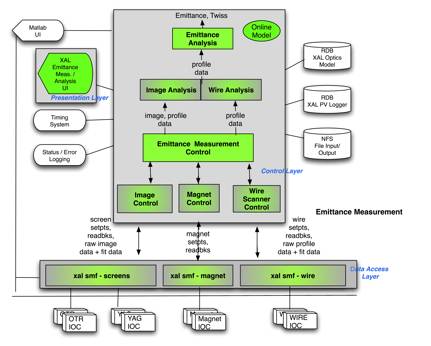

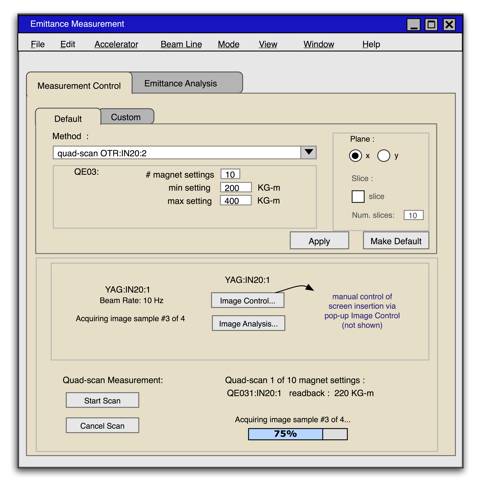

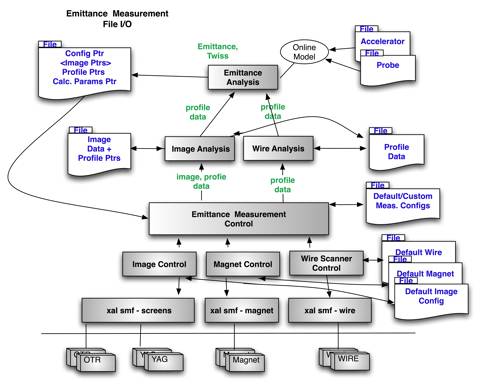

Figure 1 Emittance Measurement

Subsystem and Interfaces

Emittance Measurement is broken up into “layers”, or

components. At the lowest level is device I/O, while at the highest level

emittance calculations are output. The following section details the

functionality and requirements for each component in the Block Diagram.

2.3.2 Emittance Measurement Components

Functionality of emittance measurement is divided into the

following components:

Š Low

level xal smf (simple machine format) classes that provide channel access

value-added “wrappers” for the input and output of EPICS process variables for

all devices.

Š Image

Control for controlling all YAGS, OTRS

Š Magnet

Control for new LCLS magnet-like devices

Š Wire

Scanner Control for all WIREs

Š Emittance

Measurement Control

o Controls

measurement method, diagnostic device selection, progress tracking,

error/status/machine state logging

Š Image

Analysis for screens

o Collects

# image samples times (# screens

or # magnet settings or # slices) sets of image data and even more associated

profile data -times the # fitting algorithms

o Provides

graphical tools for the user to analyze screen images and their associated

projected beam profiles in detail

Š Wire

Analysis for wires

o Collects

# wire scanners times (# magnet settings) sets of profile data – times

the # fitting algorithms

o Provides

graphical tools for the user to analyze projected beam profiles in detail

Š Emittance

Analysis

o Read

transfer matrices from on-line model

o Calculate

Emittance and Twiss parameters and associated standard deviations

o UI:

display phase space, scatter plot of results along with standard deviations

o Perform

beta matching

Š Online

Model

o Contains R matrix values for all points along the beamline for calculating emittance / Twiss

Each of these functions are discussed in detail below.

2.3.2.1 Low level device control (xal smf)

Xal provides a set of value-added java classes which

communicate via channel access to accelerator-type devices. (Refer to XAL Accelerator Class

Hierarchy)

These simple machine format (smf ) classes will be modified where necessary to communicate with LCLS IOC epics data. Additional classes will be added for the new screen profile monitors.

2.3.2.2

Image Control

The Image Control component is used by Emittance

Measurement, Bunch Length Measurement, and the Image Control GUI. Image Control

uses the smf layer for communication with YAG/OTR controllers (IOCs).

Image Control for emittance measurement includes control

for:

Š Common

“number of image samples” setpoint for all (multi-)screen device(s) involved.

Š Common

“number of background image samples” setpoint for for all (multi-)screen

device(s) involved.

Š Number

of slices per image (1-N)

Š Selection

of x or y plane setpoints

Š Beam

rate control setpoint

Š Full

image / cropped image / fitted

beam profile setpoints to control data processing of raw data readbacks

Š Subtract

/ don’t subtract background image setpoint

Š Save

as default configuration

Magnet

Control

For commissioning, magnet control could be directly via smf.

Eventually stand-alone magnet control will have a GUI and support classes layered on top of smf.

Magnet control for emittance measurement includes control

for:

Š Magnet

minimum setpoint

Š Magnet

maximum setpoint

Š Number

of settings

Š Save

as default configuration

2.3.2.3

Wire Scanner Control

Refer to Doug’s document Wire Scanner EDD; also Wire Scanner

Control under Interfaces section below. The Wire Scanner Control uses the smf

layer to communicate with the Wire Scanner IOC.

Control for emittance measurement includes:

Š Scan

ranges and detectors

Š Current

normalization selection

Š Centroid

normalization selection

Š Save

as default configuration

2.3.2.4 Emittance Measurement Control

Configures, controls, and tracks the requested emittance

measurement:

Š Measurement

method and diagnostic device selection (further detailed below)

o Save

emittance measurement configuration

Š Start

measurement

Š Cancel

measurement

Š Track

progress of overall measurement

Š Track

progress of individual scans within overall measurement

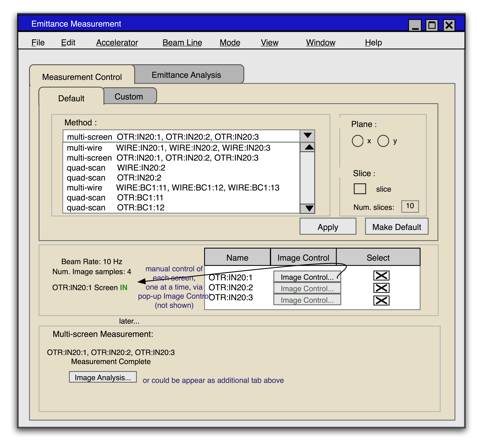

o UI:

for screen measurements, display “free-run” image of each screen as it is

inserted

Š Capability

to Restore last emittance measurement configuration and associated data

o Emittance

measurement configs – default and custom

o Image

data

o Fitted

Beam Profile data (same format for screens and wire scanners)

o Emittance

and twiss calculations

Š Report

status/errors to various clients (event log, console, cmlog, elog)

Š Store

machine state at time of measurement to PV Logger

Measurement Method and

Diagnostic Device Selection

Provide emittance measurement method selection, to include

(more detail below):

Š Multi-wire

measurement

Š Multi-screen

measurement

Š Quad-scan

using one wire

Š Quad-scan

using one screen

Š Slice

emittance using quad-scan with one screen

2.3.2.4.1 Multi-wire

Š Select

“n” number of wire scanners, where “n” >= 3

Š Each

wire scanner may have a unique default configuration

Š Each

wire is inserted and scanned consecutively, automatically

2.3.2.4.2 Multi-screen

Š Select

“n” number of screens, where “n”

>= 3

Š Each

screen must have identical default configuration

Š Each

different screen is inserted and measured consecutively, under manual control

Š For

each screen, “I” number of images (beam pulses) are requested

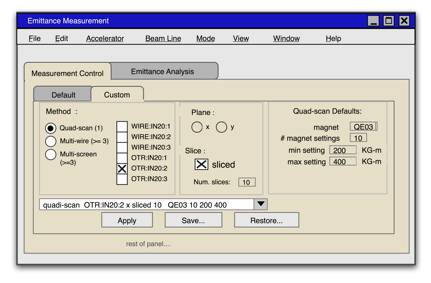

2.3.2.4.3 Quad-scan

Š Select

a) magnet and b)one wire or screen

Š Note:

new LCLS magnets only prior to commissioning

Š Default

magnet configuration, as defined via emittance measurement application, is used

for the measurement, unless user overrides via Magnet Control

Š Chosen

magnet associated with wire or screen is incrementally stepped with “n” number

of setpoints, from a minimum setting to a maximum setting (in kG-m).

Š For

a screen - the screen is inserted

“In” via user command, and once inserted, the magnet is stepped through its “n”

setpoints manually on command. The screen is then parked in the “Out” position

on command.

o “I” number of images (beam pulses) are

requested per magnet setting

2.3.2.4.4 Slice (using quad-scan and screen)

Š All

requirements for quad-scan above, but using a screen only; also select number of slices

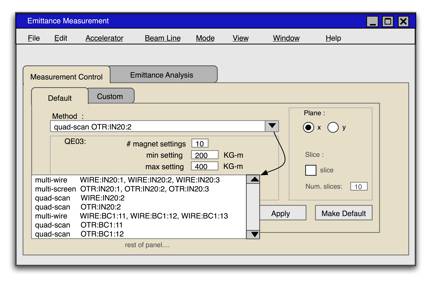

2.3.2.4.5 Measurement Method configurations

Š Provide

a default set of measurement methods, according to Table 1

Š Also

provide for “custom” user-defined measurement configurations, with any

combinations of parameters from Table 1.

Š Configuration

parameters to include wire(s), screen(s), magnet devices/settings, plane (x,y),

number of slices

2.3.2.4.6

Device Configurations

Š Provide

default configuration settings for each device which are unique to the

Emittance Measurement application

Š User

may override defaults for a device using Image Control, Wire Scanner Control,

or Magnet Control

Š Configuration

parameters include device setpoints – generally all relevant controls

available via Image Control, Wire Scanner Control, Magnet Control

2.3.2.5 Image Analysis

Image Analysis is a component used by Emittance Measurement, Bunch Length

Measurement, and Image Control. Image Analysis monitors requested data and can

display to a GUI when the user desires a detailed view of any image and its

associated beam profiles.

Refer to http://www.slac.stanford.edu/~zelazny/slaconly/LCLS/Image%20Analysis%20and%20Control/ ; “Image Analysis” and “Individual

Image Analysis” for the proposed UI for Image Analysis.

Image Analysis for emittance measurement includes:

Š Provide

raw image, fitted beam profiles, “free-run image”

o Beam

profile data is fitted using all of the following algorithms:

§ Gaussian

§ Asymmetric

Gaussian

§ RMS

with Baseline Cut

§ Other(s)

TBD – algorithm expansion capability

Š UI:

image data has auto/manual crop, auto/manual background image subtraction

Š For

screen(s) involved in measurement (multi-screen or quad-scan using a screen),

per screen (OTR/YAG):

o Provide

“I” number of images acquired by the measurement , (UI: scrollable)

§ Selectable

in x or y plane.

§ Selectable

by screen name (if more than one) -

Data Set #1-#N = individual

screen names

§ Provide

beam profile data selectable by fitting algorithm.

§ Calculated

parameters include:

Š …

Š For

quad-scan with screen, all of the above except:

o One

plane only (x or y is indicated)

o Selectable

by quad setting

Data Set tabs #1-#N = quad

settings (numeric or BDES?) -

o (UI)

With “I” number of images displayed,

selectable by slice number.

§ Highlight

slice area (or line boundaries either side) currently being displayed by slice

number selection

o Calculated

parameters (UI: adjacent to each image) include calculated emittance (for all

“I” number of images)

o ?Calculate

sliced energy spread using the slices – possible at OTR4, OTRS1, YAGS2,

OTR30, at a minimum. (is sliced energy spread stand-alone, or used in

conjunction with a quad-scan?)

Š For

sliced quad-scan with screen, all of the above, except:

o Selectable

by Slice #, 1-N

o Calculated

parameters include calculated emittance per slice, and for all “I” number of

images

2.3.2.6 Wire Analysis

Wire Analysis is used by Emittance Measurement and Wire

Scanner Control. It is similar to Image Analysis, with the exception that no

images are provided or manipulated; only beam profiles, in the same format as

the screen beam profiles.

Wire Analysis for emittance measurement includes:

Š Provide

fitted beam profile data, parameter data

o Data

is fitted using various algorithms:

§ Gaussian

§ Asymmetric

Gaussian

§ RMS

with Baseline Cut

§ Other(s)

TBD – algorithm expansion capability

Š UI:

edit data / recalculate beam size parameters capability

Š For

wire(s) involved in measurement (multi-scan, quad-scan using wire), per wire:

o Provide

(raw or “processed”) profile data (UI: scrollable if necessary)

§ Selectable

in x or y plane

§ Selectable

by wire name (if more than one) –

Data Set tabs #1-#N = wire names

§ Selectable

by fitting algorithm

§ Output

calculated parameters, including: …..

o Provide

ability to edit a single profile (UI only) – crop, remove points and

recompute beam size (Individual Wire Analysis)

Š Calculate

and output Projected Energy Spread parameter - for WS04 only

o Rms

beam size divided by dispersion (model parameter)

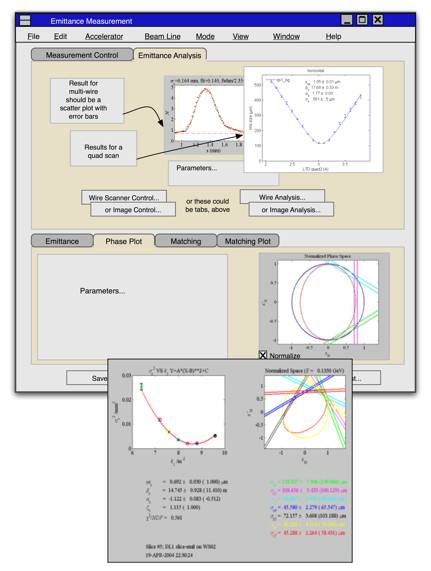

2.3.2.7 Emittance Analysis

The following Input/Output bullets were extracted from

emittance_proc.ppt, Henrik Loos, December 13, 2005

Š Input

o List

of best fit beam sizes and

standard deviations

o List

of R matrices corresponding to each measurement from online model

Š Output

o Sigma

matrix at start of beamline

o Emittance

/ Twiss parameters – calculation:

- Three independent values in

sigma matrix σ1,

σ2, σ3

- Related to measured beam size σx with R-matrix by

σx2

= R112 σ1

+ 2R11R12 σ2

+ R122

- Form linear equations for

measurement i: σx,i2 = ΣkMik σk

- Find σk by least squares fit

- Emittance is ε2 = σ1 σ3 - σ22

- Twiss parameters are β = σ1/ε, α = -σ2/ε

- Standard deviations of all

parameters

- For every slice, for every

image…

Š UI -Provide scatter and phase space plots

for all measurement methods

o Details

- axis labels, when displayed data

is averaged, etc

o

Š Capability

to “drill down” to either Image Analysis or Wire Analysis in order to view data

in more detail; also to modify. Any parameter recalculations as a result of

data modification at the Image or Wire Analysis layer should be able to be

easily propagated back up to the Emittance Analysis layer for emittance

recalculations.

Š Save

“signature” of measurement – pointers to measurement configuration, image

data, profile data, calculated parameters for subsequent “Restore Last

Measurement” option

2.3.2.7.1 Comparison with Model : Betatron Matching

Š Use

fitted emittance and machine settings from PVLogger to calculate measured beam

transfer matrices

Š Use

on-line design model to compare with fitted emittance and Twiss

Š Predict

changes to specified magnets to achieve design twiss parameters at specified

location

2.4 Interfaces

2.4.1 User Interface

Š Allow

for UI in XAL framework

Š Allow

for matlab UI

Many of the following sections contain mocked up

user-interfaces for the xal framework. These mocked-up UIs have helped to

further refine requirements.

2.4.1.1

Image Control UI

Refer to http://www.slac.stanford.edu/~zelazny/slaconly/LCLS/Image%20Analysis%20and%20Control/ ; “Image Control” for the proposed UI

for Image Control. A similar GUI for image control will be incorporated for

Emittance Measurement, either as a pop-up window or additional tab, (only when

measurement involves screens).

2.4.1.2

Wire scanner Control UI

Refer to the Wire Scanner Control EDD for stand-alone Wire

Scanner Control User Interface. The Wire Scanner Control GUI could be another

tab on Emittance Measurement or a separate pop-up window.

2.4.1.3

Emittance Measurement Control UI

2.4.1.3.1

Default Measurement Configuration

2.4.1.3.2

Custom Measurement Configuration

2.4.1.3.3

Multi-wire measurement

2.4.1.3.4

Multi-screen measurement

2.4.1.3.5

Quad-scan screen measurement

2.4.1.3.6

Quad-scan wire measurement

2.4.1.4

Image Analysis UI

Refer to http://www.slac.stanford.edu/~zelazny/slaconly/LCLS/Image%20Analysis%20and%20Control/ ; “Image Analysis” and “Individual

Image Analysis” .

2.4.1.5

Wire Analysis UI

Refer to http://www.slac.stanford.edu/~zelazny/slaconly/LCLS/Image%20Analysis%20and%20Control/ ; “Image Analysis” and “Individual

Image Analysis” for the Wire Analysis and Individual Wire Analysis

functionality. For wires, ignore the images in these GUIs.

2.4.1.6

Emittance Analysis UI

2.4.2 Optics model Interface

Š The

Oracle database (RDB) contains the XAL accelerator definition, which consist of

accelerator sequences, devices (accelerator nodes) and associated PVs.

o The

accelerator definition is copied into an XML accelerator file via the tool

“Relocate”

o XAL

reads the XML file and generates an object graph view of the accelerator

(on-line model)

o Online

model reads the probe file’s initial conditions and generates a model specific

view of the accelerator

§ Contains R matrix values for all points along the beamline for calculating emittance / Twiss

Š The Oracle database also contains design model twiss parameters for all points along the beamline for beta matching

2.4.3 Channel Access (IOCs) – these become ICDs

2.4.3.1

Timing

Š Beam rate of 1Hz or 10Hz

2.4.3.1.1 Wire scanning

Š Beam

synchronous data is required for relevant WIRE, PMTs, BPMs, Toroids while wire

is scanning. (Relevant magnet

setting for one wire, quad-scan)

2.4.3.1.2 Screen insertion

Š Beam

enable/disable and rate limiting for screens is accomplished by MPS

2.4.3.2 Wire Scanner IOC

API forthcoming from Doug!

2.4.3.2.1 Setpoints

Š Setpoints

to control selection of : plane (x, y,u), toroids, BPMs, PMTs, travel (start,

stop position or scan distance), motion (scan time or scan speed, or number of

beam pulses), normalization,

2.4.3.2.2 Readbacks

Š Arrays

of raw and “processed” data for each plane (position versus beam intensity).

o Processed

data can be Current and Centroid normalized

Š Fit

parameters (sigma, etc) for each plane and for each of three algorithms

Š Measurement

status

2.4.3.3 YAG/OTR IOC

API forthcoming from Sheng!

2.4.3.3.1 Setpoints

Š Auto-crop

on/off,

Š Number

of image samples

Š Number

of background image samples

Š Auto

background image subtraction on/off

Š screen

in/out

2.4.3.3.2 Readbacks

Š Raw

image data (pixels)

Š “free-running” image

Š Fit

parameters (sigma, etc) for each of three algorithms

Š Measurement

status

2.4.3.4

Magnet IOC

2.4.3.4.1 Setpoints

Š Magnet

setting (kG-m)

2.4.3.4.2 Readbacks

Š Magnet

reading (kG-m)

2.4.4

PV logger ( Oracle RDB)

Stores entire “default” machine state at time of measurement in the Oracle RDB. Part of XAL.

2.4.5 File I/O

Refer to the following figure for modeling, data, and

configuration files.

2.4.5.1 Default/Custom Emittance Measurement Configuration Files

Š Ascii

text format stores:

o Measurement

type

o Diagnostic

device(s)

o Magnet

o Magnet

settings

o Plane

selection

o Slice

information

2.4.5.2 Profile Data Files

Š Ascii

text format

Š Matlab

format

Š Png

format

2.4.5.3 Image Data Files

Š Pixel

2.4.5.4 Emittance Files

Contains:

Š Pointers

to emittance measurement config file

Š Pointers

to profile data file

Š Pointers

to image data files when screen is involved in the measurement

Š Calculated

emittance parameters

2.4.5.5 Accelerator file (xml)

Generated from the RDB; contains accelerator sequences, nodes, PV names. Applications that use an online (or offline) model load this to gain access.

2.4.5.6 Probe file (xml)

Model type, beam initial conditions. Each app that loads the proble file “runs through” the accelerator file and generates its online R-matrix for each element involved in lattice transport (ie magnets, RF ).

2.5 Status/error reporting

Š Elog

– message to the physics log when an invasive operation occurs

Š Java

cmlog client (to be developed) such that all xal applications may output

- The event window is currently

available via the xal framework and may be used in the interim.

- The

java console window may also be used